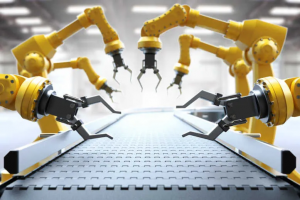

Robotics are quickly dominating the likes many industries as automation becomes a priority. From the assembly line to the surgery room, with the use of robotics in healthcare comes an efficiency and precision that often cannot be achieved by human hands. This makes robotics an obvious choice for many medical device manufacturers all over the world, and the conversion to such is drastically enhancing sterilization, employee safety, and speed of production across the industry.

Eliminating the chances of receiving defective or unsterilized medical equipment starts at the source. Because of this, companies like Tegra Medical are seeking to fully automate a large portion of all their manufacturing with the help of Tecomet Inc., a leading robotics engineering firm.

Together the companies are finding ways to create efficiency in production across the board. Using robots for making razor-edged scalpels, for instance, helps to prevent the safety hazards associated with human workers manufacturing them. The manufacturing of a high-precision apparatus like a heart-valve is also being enhanced through the consistency of robotics manufacturing, minimizing the chance for human error on a device that may cost a patient their life if it malfunctions.

These companies aren’t the only ones making way in the industry. NuTec has recently begun manufacturing Cleanroom SCARA robots that are purposed for manufacturing syringes in an ultra-sanitized, isolated environment. This technology is already being utilized by a few companies, just in time to assist with a mass demand for vaccination syringes for COVID-19. U.K. company, Riverside Medical Packaging is implementing robotic packaging services as well, to eliminate the previously used assembly line, enhance sterilization of products, and increase the speed of production.

Some companies are even transcending those standards of robotics, like German-based company, Festo, which has gone so far as to create a fully operable robotic assistant that uses AI learning to effortlessly adapt in the workplace and perform the hazardous or time-consuming functions of medical production.

With the right human counterparts to aid in management and operation, robotics will only continue to expand within this industry. With precision, speed, and intricacy, the manufacturing capabilities of such technology will mean faster and more reliable medical device production, which is critical in order to meet rising demands.